Project:3D Printer (rapman)

Contents |

Original configuration

Oxhack was given a 3D printer 22/7/2014. (Original message: https://groups.google.com/d/msg/oxford-hackspace/lXL9Nor7PxQ/9-hlTiBnFI4J )

It's a bitsfrombytes rap-man 3.0.

It runs G-Code directly from the built-in sd card reader.

the process for printing something is:

- get STL file (you can download this or use your favourite 3d cad tool to draw something)

- run the STL file through their (windows-based) Axon software which makes a g-code file

- transfer gcode file to printer using SD card

- choose file using the tiny menu and buttons on the printer and hit 'go'

- wait while it prints.

The 'slicer' software required is called Axon. You need version 2.1 (maximum - 3.0 doesn't look like it'll work with this machine - I suspect we could use some customised settings fore Slic3r, but figured the intended software was best place to start)

You can get axon here:

Problems:

- Big SD cards don't work - needs to be 2GByte max, I suspect.

- it's slow. I think this is due to a g-code post-processing failure, possibly due to reliance on python 2.7.3 (and I might have others installed). So Axon makes a g-code output, but then appears to attempt to post-process it, which results in an empty file. If you run the raw-g-code output, a number of things are wrong, including the extruder temp.

- Print is a little too large - printed a 1cm cube which came out about 5% too big

- The g-code output (at least prior to the post-pro) has the extruder temp set wrong. It was set correctly in the software. This might get adjusted by the post-pro python (that wasn't working for me), but I had to hand-hack the g-code file to get the nozzle up to extruding temp (~260 degrees)

Potential improvements (volunteers required):

- can you make Axon work correctly? Maybe we need an older version? maybe just a clean-machine install or VM - or maybe set up slic3r?

- we need a way to mount the cable reel somewhere - it's floating about at the moment

- The machine would benefit from a heated bed - we could make one or buy one (if we can find the right size)

- the extruder takes AGES to heat up. The PSU is only a 12V unit, and the wires heading toward the heater are pretty skinny. Measuring the VDrop accross the wires would be good start (while the extruder is heating up) - if there's significant drop, then fatter wires might heat it up quicker, otherwise, we'd need to up-the-voltage to get it to heat faster. The connector on the side (near the SD card) is not inserted fully due to some mechanical interference. This could be improved and may be contributing to slow heating

In progress

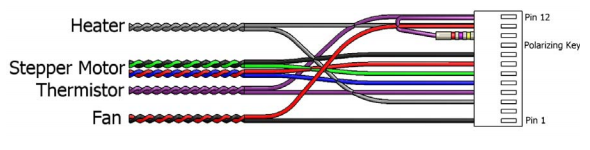

The printer is currently useless. The original control board has been disconnected, and most of the wires are now terminated with square header connectors, which don't directly connect to it. Not all of these bundles of wires are easily identified: one set is labelled "Extruder" and two (!) both say "Y".

The Extruder connection *does* have suitable pins, although not the same number as there are wires, and one of them is broken.

The power supply has also been butchered, and now ends with bare wire.

Ways to make it useable again:

Replace the control board

This would be finishing the job. We'd have to obtain such a board.

Alternatives include R2C2 or the Rapman 3.1/3.2 upgrade kits.

Put the old board back

Undo all the previous work: untaping and untwisting all the extra wires, to obtain bare wire endings that can be screwed into the original board.

Alternatively, add pins to the old board so that the square headers can be plugged directly onto it. As a temporary fix, jumper wires will do, but the board's screw terminals don't grip these very well.

The "Extruder" connection should be connected up according to this diagram:

A new power supply will have to be found. It's a standard-looking connector, so any powerbrick that comes with a selection of heads should do it.

See also the Setup Manual